- #Xbar and r chart excel template generator

- #Xbar and r chart excel template series

- #Xbar and r chart excel template download

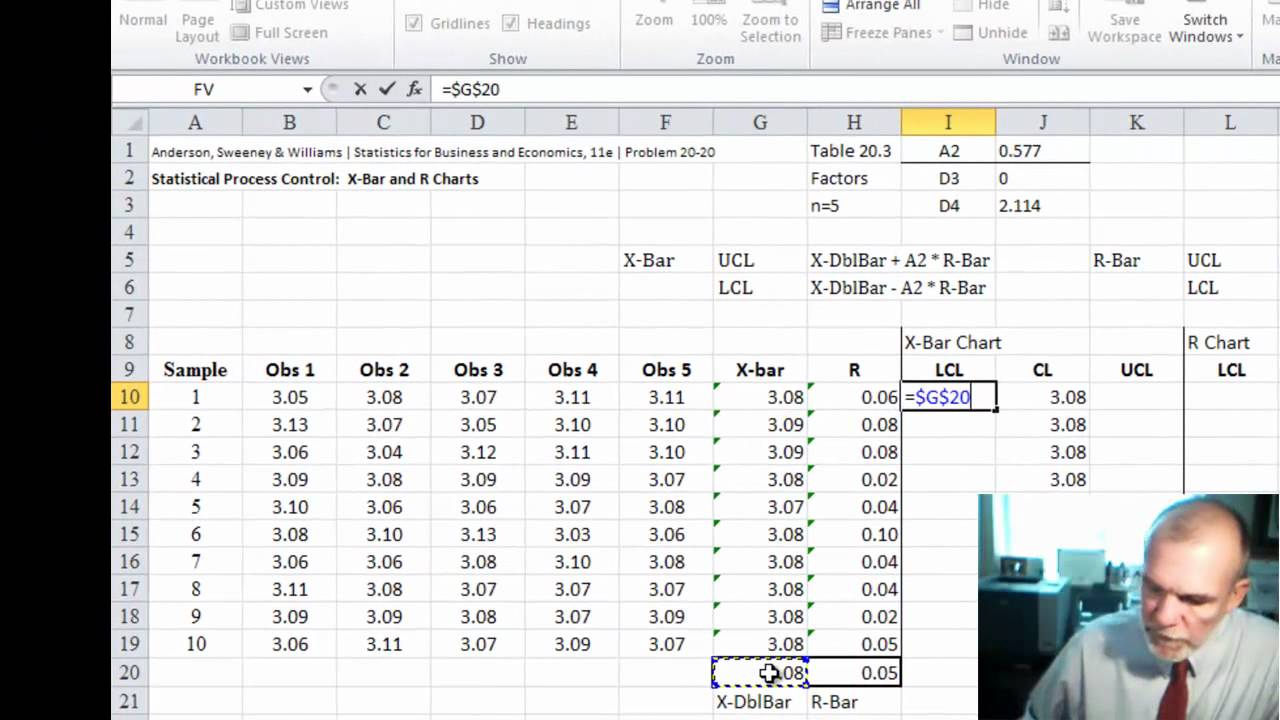

Determining the appropriateness of the data in relation to the tolerances is the job of a Measurement System Analysis (MSA). While the sample data used is integers, it could be collected to any degree of precision that is appropriate for the tolerances. This type of data is measurable on a continuous scale. The first type of charts we are going to look at are for Variables data. Therefore, let us focus on Control Charts categorized into the following: A flow chart of some of the major Control Chart types and their classifications. Share article on LinkedIn and submit the LinkedIn post link in this formĬreate an innovative slogan for 5S and submit it in this form That relationship is described with a histogram in Capability Analysis. W Edwards Deming demonstrated that approximately 94% of all variation is “common cause.” This allows employees to focus on the 6% of variation that is “special cause.” Engineering tolerances, or the Voice of the Customer (VoC), are never included on a Control Chart. The KPI, its average, and limits show the variation inherent in the system. However, each of the charts has been hyperlinked to review just the chart you are interested in at the moment.Ĭontrol Charts are a way to listen to the Voice of the Process (VoP). As a result, the discussion of each is a bit redundant when considered as a whole. The six Control Charts we will review all follow this same premise. When points fall outside of these limits, they indicate something unusual has occurred (that is, “special cause” or “assignable cause” variation). The center line and control limits can be calculated from historical data. Control Limits are then added at three standard deviations from that average. This is done by plotting Key Process Indicator (KPI) statistics with an average for reference. They are used to show the typical variation in a process (that is, “common cause” variation).

#Xbar and r chart excel template download

#Xbar and r chart excel template generator

Upper Control Limit = Mean of Moving Range * D4 Upper and Lower control limits are calculated with the similar formula of I chart.

#Xbar and r chart excel template series

Consider a data series Data PointsĪbsolute value of the difference between the previous point and the current point is noted as Moving Range in that row.įor moving range chart, the central line will be the Average of Moving Range. Moving range is the difference between two consecutive points of a data series. Because, we are considering the next data point to calculate the moving range, we can consider a subgroup size of 2. Hence, we consider it as same as of subgroup size 2. For Subgroup size of 1, statistics does not recommend E2 value. In this method, every time only one sample is taken. *Note : I chart & MR chart is possible only when we follow Simple Systematic Sampling. Lower Control Limit = Mean – E2 * R-bar E2Į2 is a constant derived according to the control chart constant table, which is available on the internet. Construction of I-MR Chart I ChartĬentral Line = Mean of all individual values of the data set In this sampling method, we take one piece of sample at a regular interval of time. Sampling Method for I-MR ChartĪ simple systematic sampling method calls for I-MR Chart. In this article, we will see the construction of I & MR charts and will discuss the need for MR chart in the next article on Xbar-R Chart. I MR Chart consists of two plots namely, Individual Value Chart (I) and Moving Range Chart (MR). Here depending on the type of data we possess the type of control chart, and the process data will vary. It helps the process owner to predict when his process is going to produce a defect.Ĭontrol charts are made by drawing mean line and control lines superimposing the simple line chart of process data*. We have already seen what a control chart is in an earlier short article.

0 kommentar(er)

0 kommentar(er)